Description

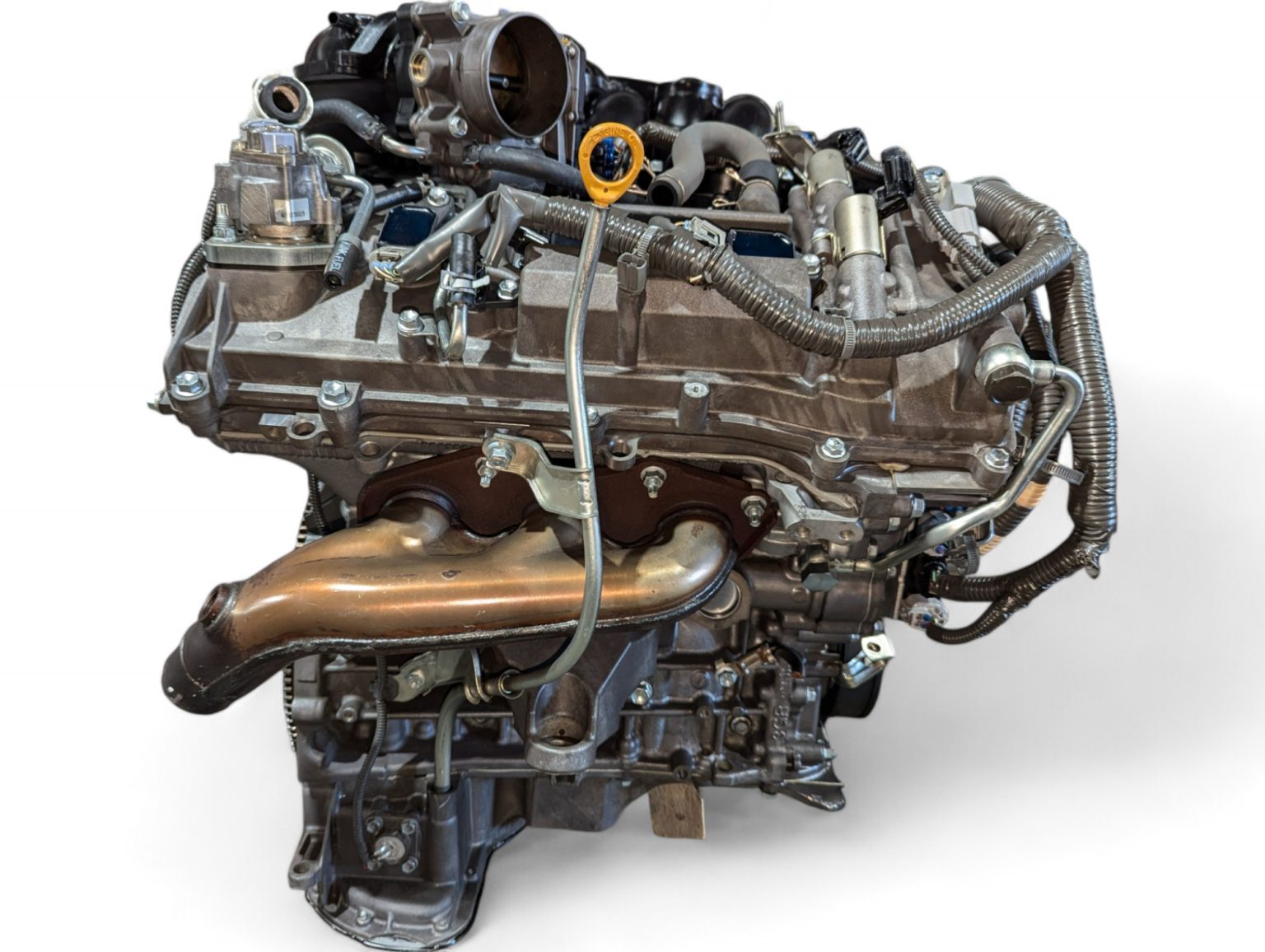

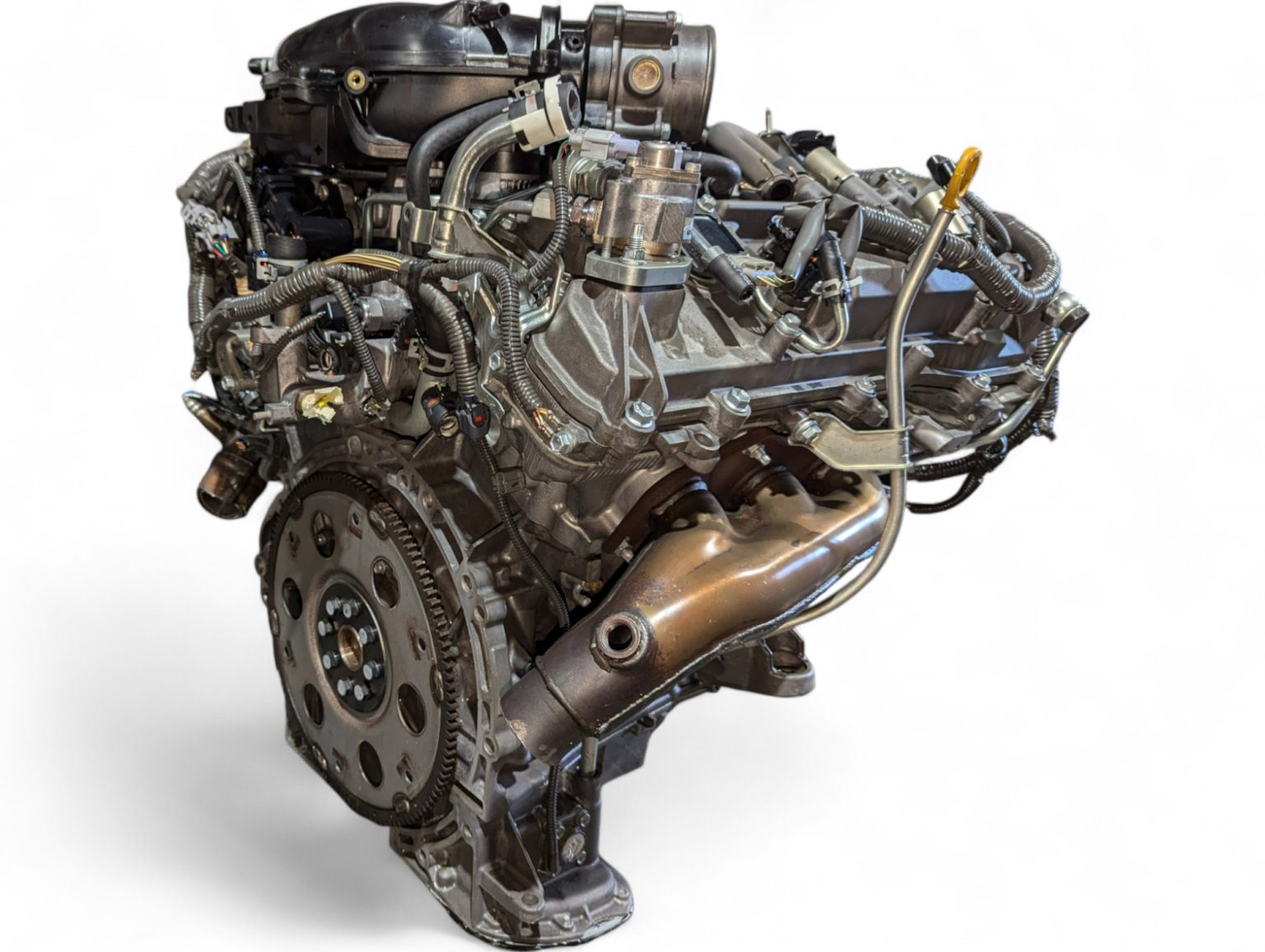

2006 Lexus GS300 3.0L V6 RWD Engine JDM 3GR 0058440 *Damaged* by Lexus is listed under Lexus GS300 Engines. This comprehensive description helps verify fitment, identify part numbers, and plan installation with clarity.

Identification and basics:

– MPN: LEXUS

– Reference price (USD): 1499.00

Key features:

– Correct mounting geometry and verified connectors for the listed applications where specified by supplier data.

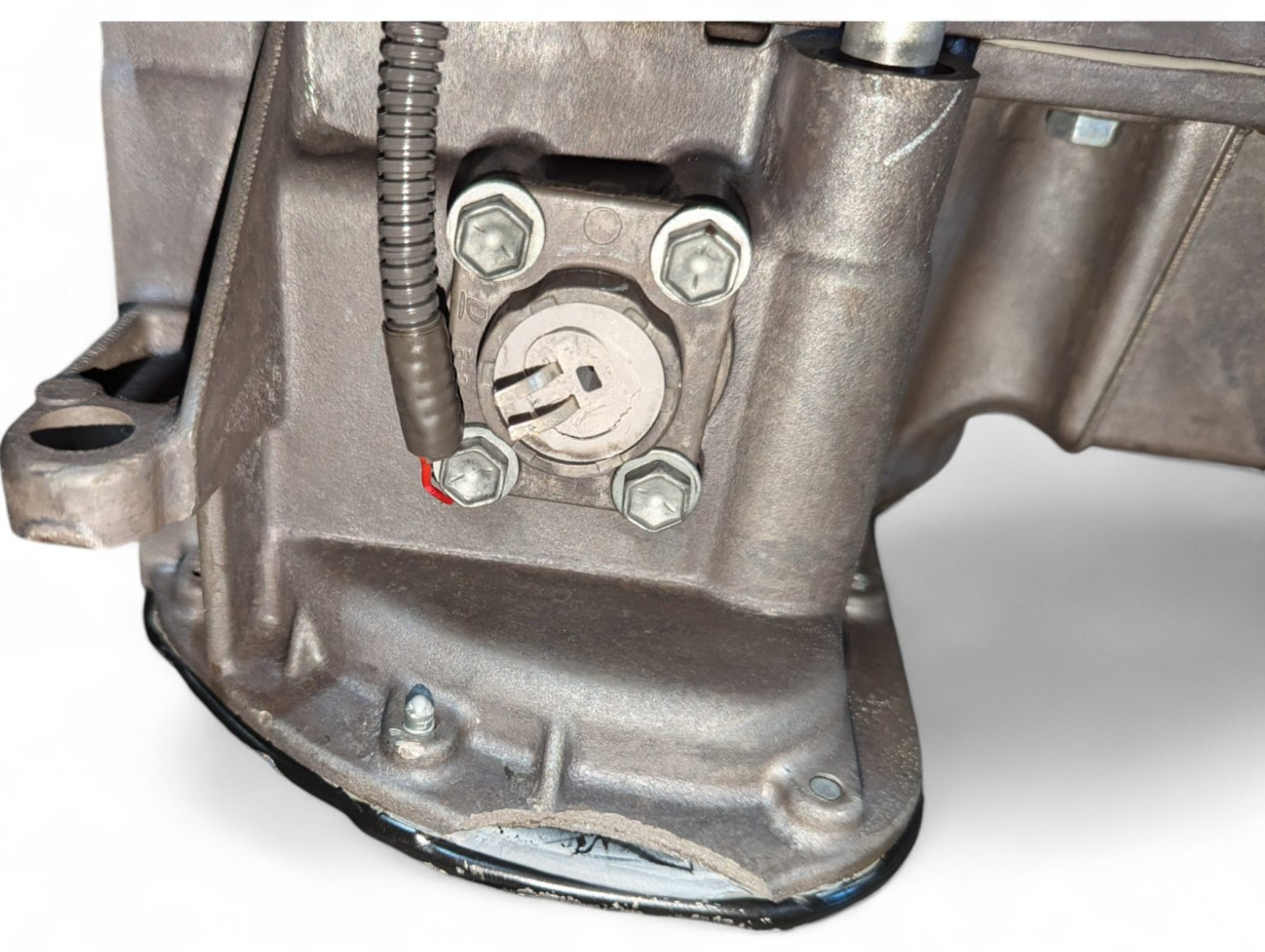

– Supplied as shown or stated; ancillaries included only when explicitly specified.

– Traceability: match part numbers and orientation before purchase to reduce returns.

Technical specifications:

– Manufacturer Part Number: LEXUS

Compatibility checklist:

– Confirm drivetrain orientation and bell pattern.

– Cross-check ECU, immobilizer, and sensor compatibility.

– Match emissions family and generation.

– Compare connector shapes, mounting bosses, and hose routing.

Installation guidance:

– Professional installation recommended.

– Replace wear items during install: belts, seals, filters, plugs, fluids.

– Follow torque sequences and prime the oiling system prior to first start.

– Bleed the cooling system and verify fueling integrity.

Post-install checks:

– Perform compression or leak-down tests.

– Scan for DTCs and resolve wiring or vacuum inconsistencies.

– Verify idle quality, fuel trims, coolant temps, and oil pressure at operating temperature.

Packaging and handling: Inspect on delivery and note any damage with the carrier. Keep packaging until functionality is confirmed.

Buyer guidance: Only components explicitly shown or stated are included. If your application differs from the parameters shown, select a variant that matches your configuration.

Search keywords: lexus, gs300, 3.0l, 20-20, jdm, engine, long block, 2006, rwd, 3gr, 0058440.

Fitment notes:

– Measure sensor leads and compare connector indexing.

– Confirm crank and cam trigger patterns match your ECU strategy.

– Verify accessory bracket offsets and pulley alignment to avoid belt walk.

Technical references:

– Use OEM literature for torque specs and lubricant grades.

– Record baseline idle, MAP/MAF values, and coolant temps for diagnostics.

– If swapping, document pinouts and wire colors during harness integration.

Maintenance plan:

– After 100–300 km, re-torque critical fasteners where specified.

– Change oil and filter after break-in. Inspect for metal debris.

– Monitor misfire counters and long-term fuel trims.

Quality checklist:

– Inspect for oil or coolant seepage at gaskets and core plugs.

– Verify PCV routing and vacuum integrity for stable idle.

– Confirm charging output and ground paths under load.

Fitment notes:

– Measure sensor leads and compare connector indexing.

– Confirm crank and cam trigger patterns match your ECU strategy.

– Verify accessory bracket offsets and pulley alignment to avoid belt walk.

Technical references:

– Use OEM literature for torque specs and lubricant grades.

– Record baseline idle, MAP/MAF values, and coolant temps for diagnostics.

– If swapping, document pinouts and wire colors during harness integration.

Maintenance plan:

– After 100–300 km, re-torque critical fasteners where specified.

– Change oil and filter after break-in. Inspect for metal debris.

– Monitor misfire counters and long-term fuel trims.

Quality checklist:

– Inspect for oil or coolant seepage at gaskets and core plugs.

– Verify PCV routing and vacuum integrity for stable idle.

– Confirm charging output and ground paths under load.

Fitment notes:

– Measure sensor leads and compare connector indexing.

– Confirm crank and cam trigger patterns match your ECU strategy.

– Verify accessory bracket offsets and pulley alignment to avoid belt walk.

Technical references:

– Use OEM literature for torque specs and lubricant grades.

– Record baseline idle, MAP/MAF values, and coolant temps for diagnostics.

– If swapping, document pinouts and wire colors during harness integration.

Maintenance plan:

– After 100–300 km, re-torque critical fasteners where specified.

– Change oil and filter after break-in. Inspect for metal debris.

– Monitor misfire counters and long-term fuel trims.

Quality checklist:

– Inspect for oil or coolant seepage at gaskets and core plugs.

– Verify PCV routing and vacuum integrity for stable idle.

– Confirm charging output and ground paths under load.

Fitment notes:

– Measure sensor leads and compare connector indexing.

– Confirm crank and cam trigger patterns match your ECU strategy.

– Verify accessory bracket offsets and pulley alignment to avoid belt walk.

Technical references:

– Use OEM literature for torque specs and lubricant grades.

– Record baseline idle, MAP/MAF values, and coolant temps for diagnostics.

– If swapping, document pinouts and wire colors during harness integration.

Maintenance plan:

– After 100–300 km, re-torque critical fasteners where specified.

– Change oil and filter after break-in. Inspect for metal debris.

– Monitor misfire counters and long-term fuel trims.

Quality checklist:

– Inspect for oil or coolant seepage at gaskets and core plugs.

– Verify PCV routing and vacuum integrity for stable idle.

– Confirm charging output and ground paths under load.