Description

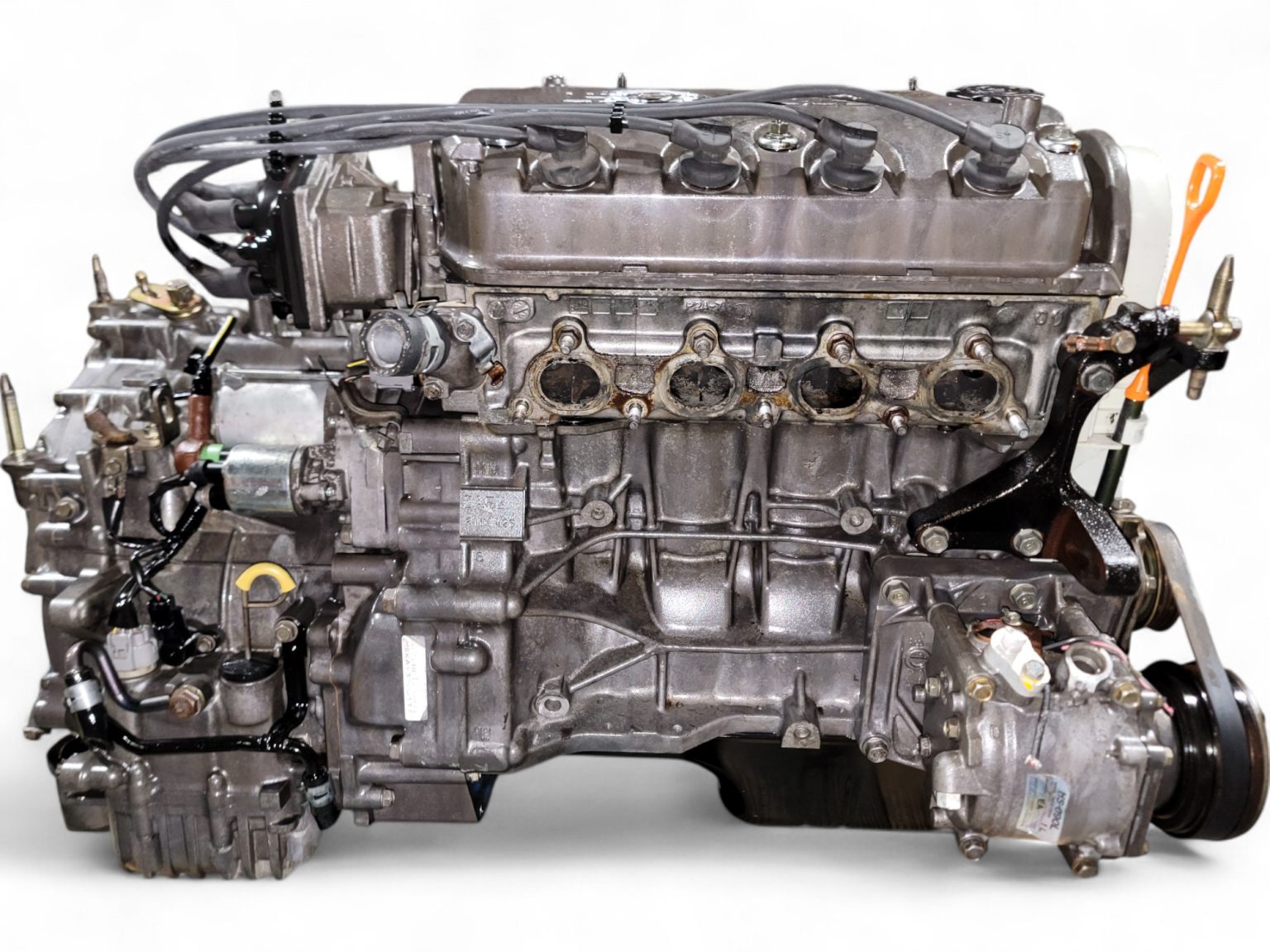

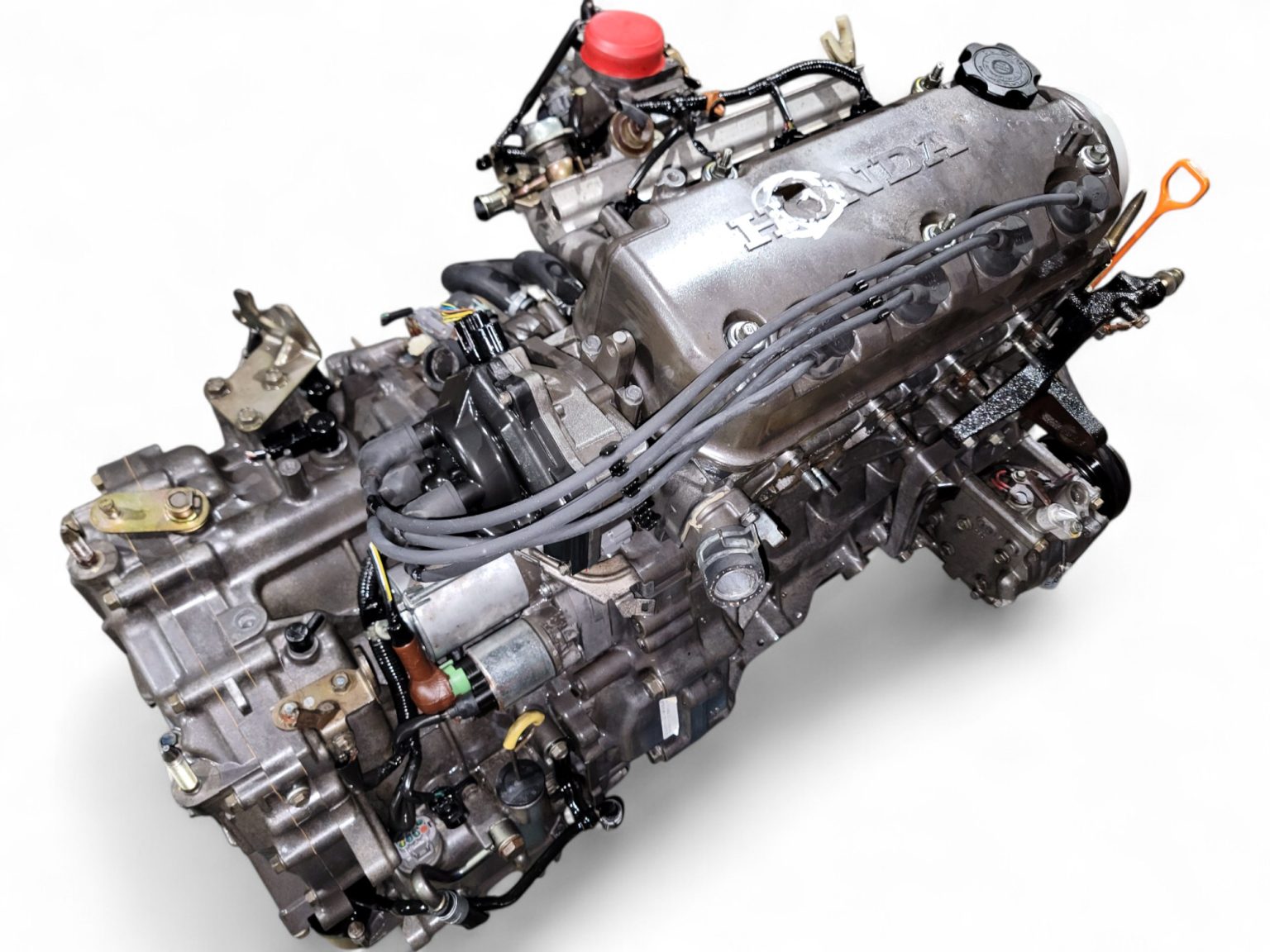

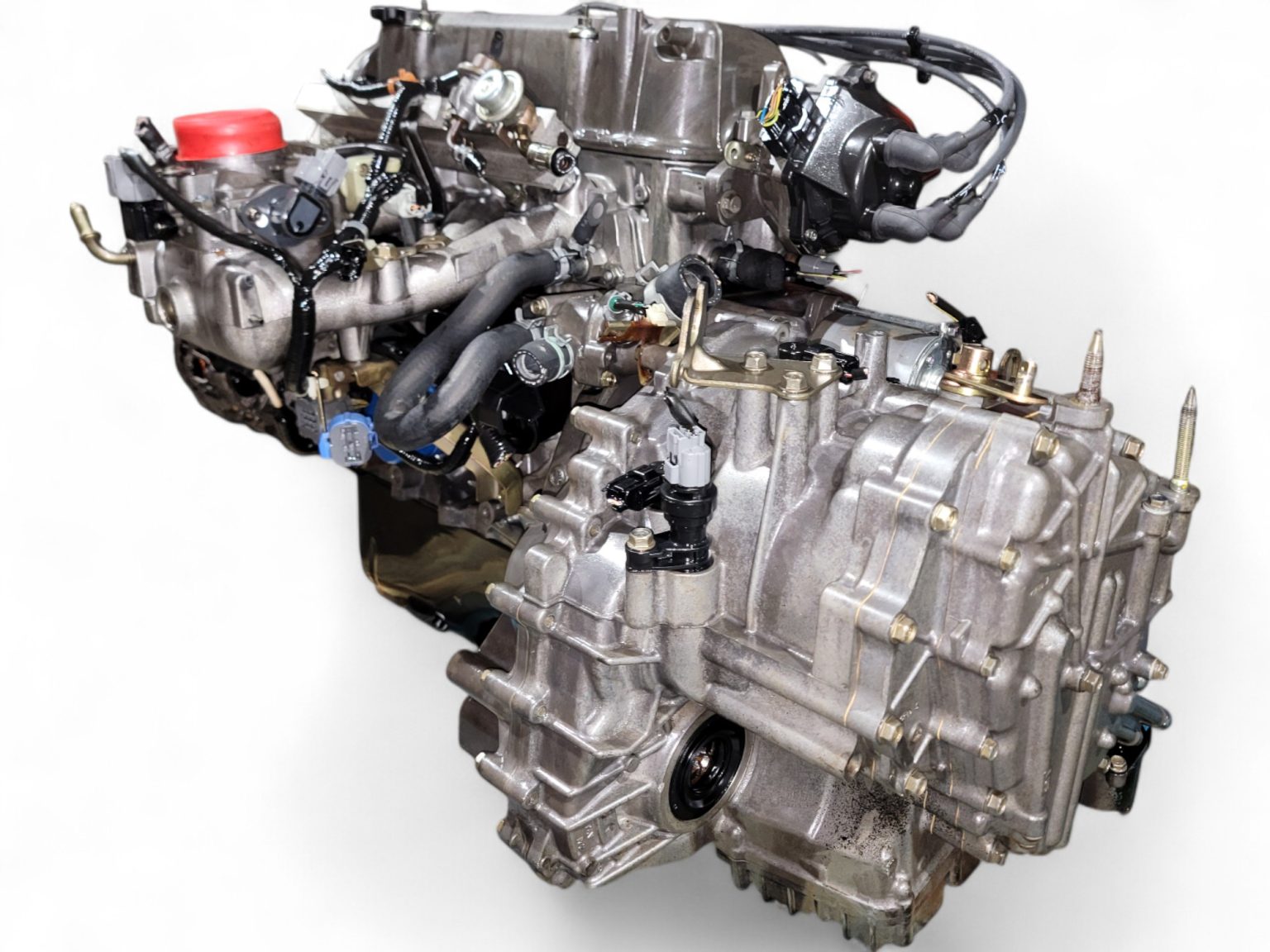

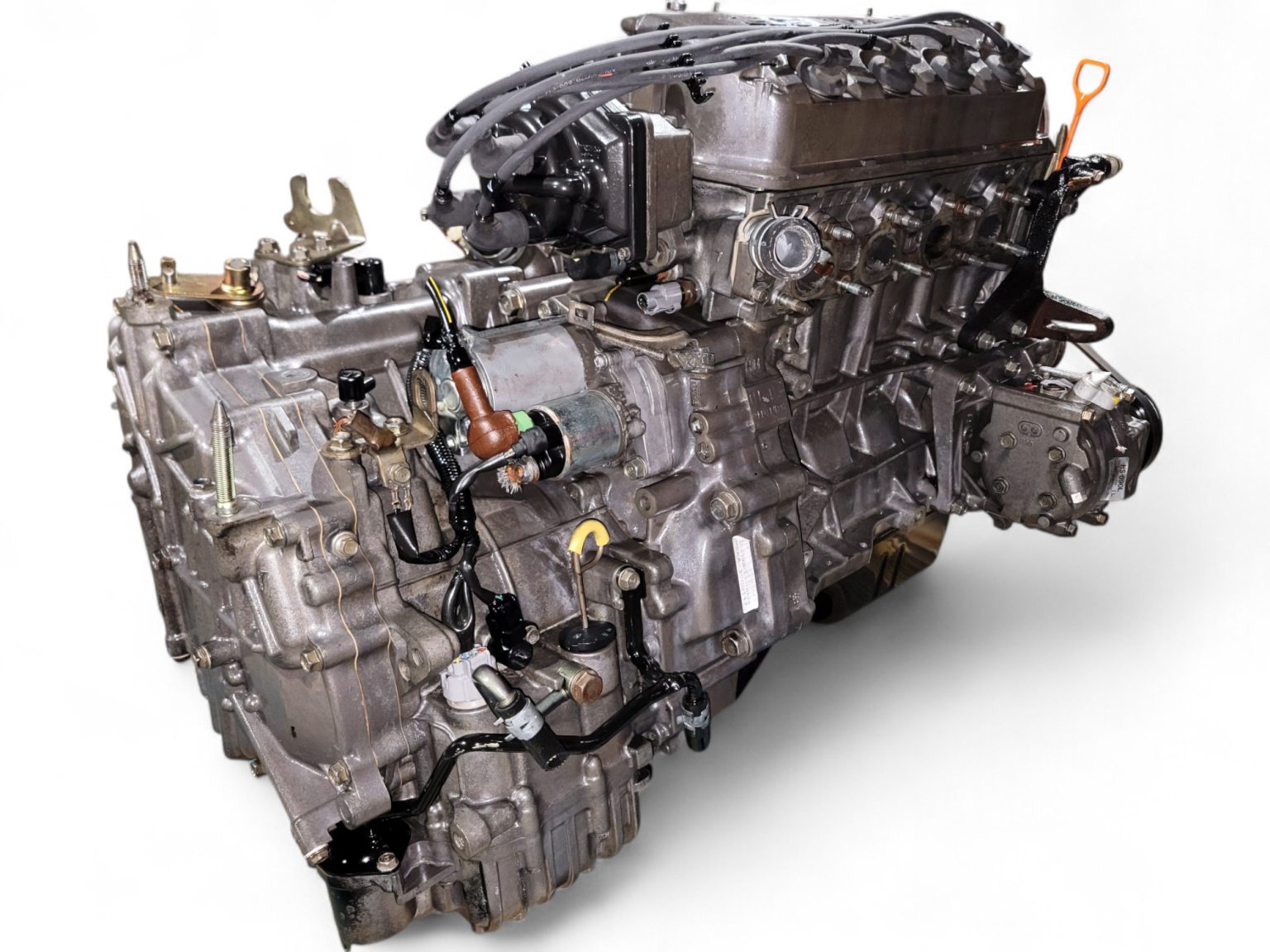

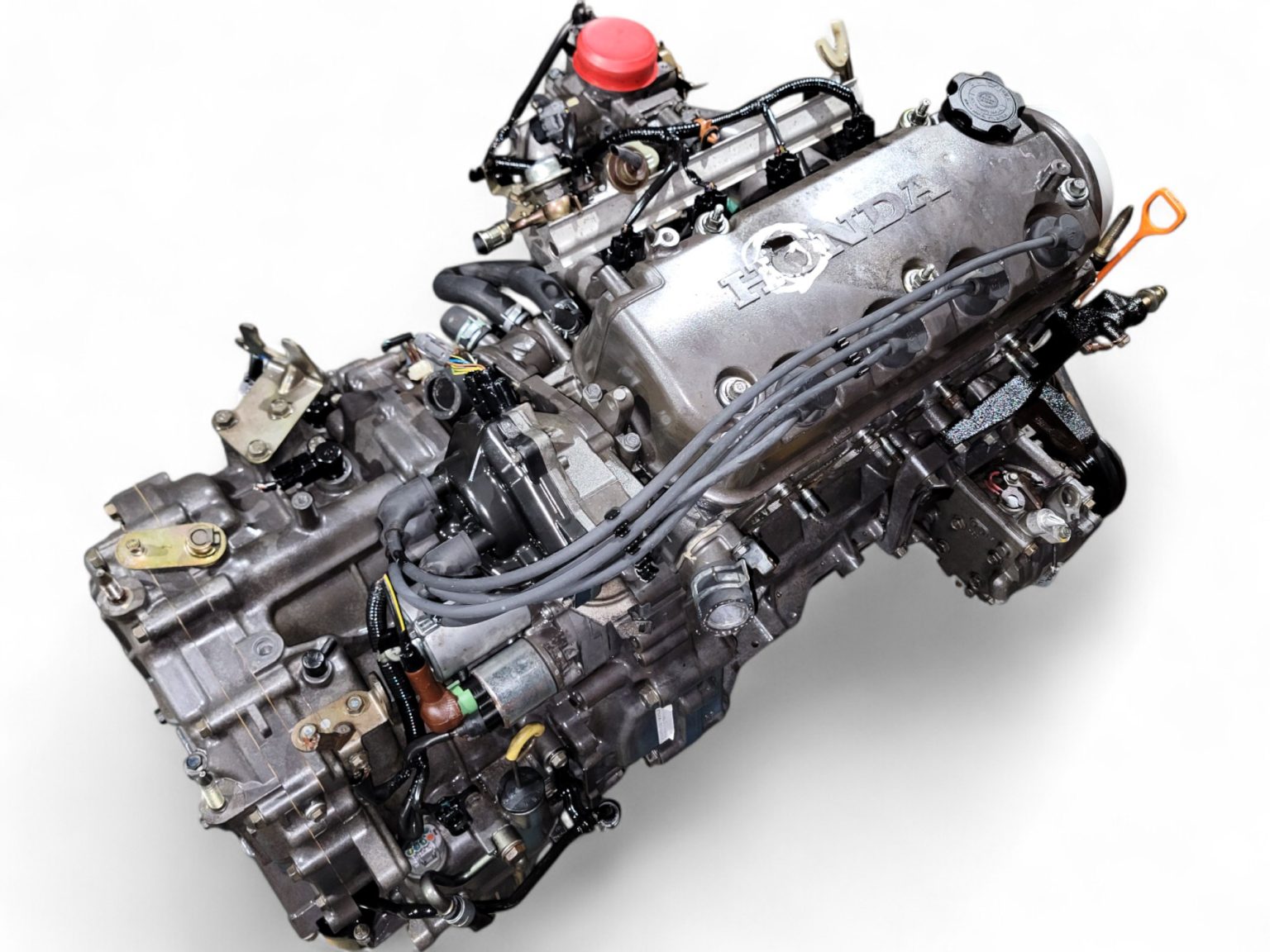

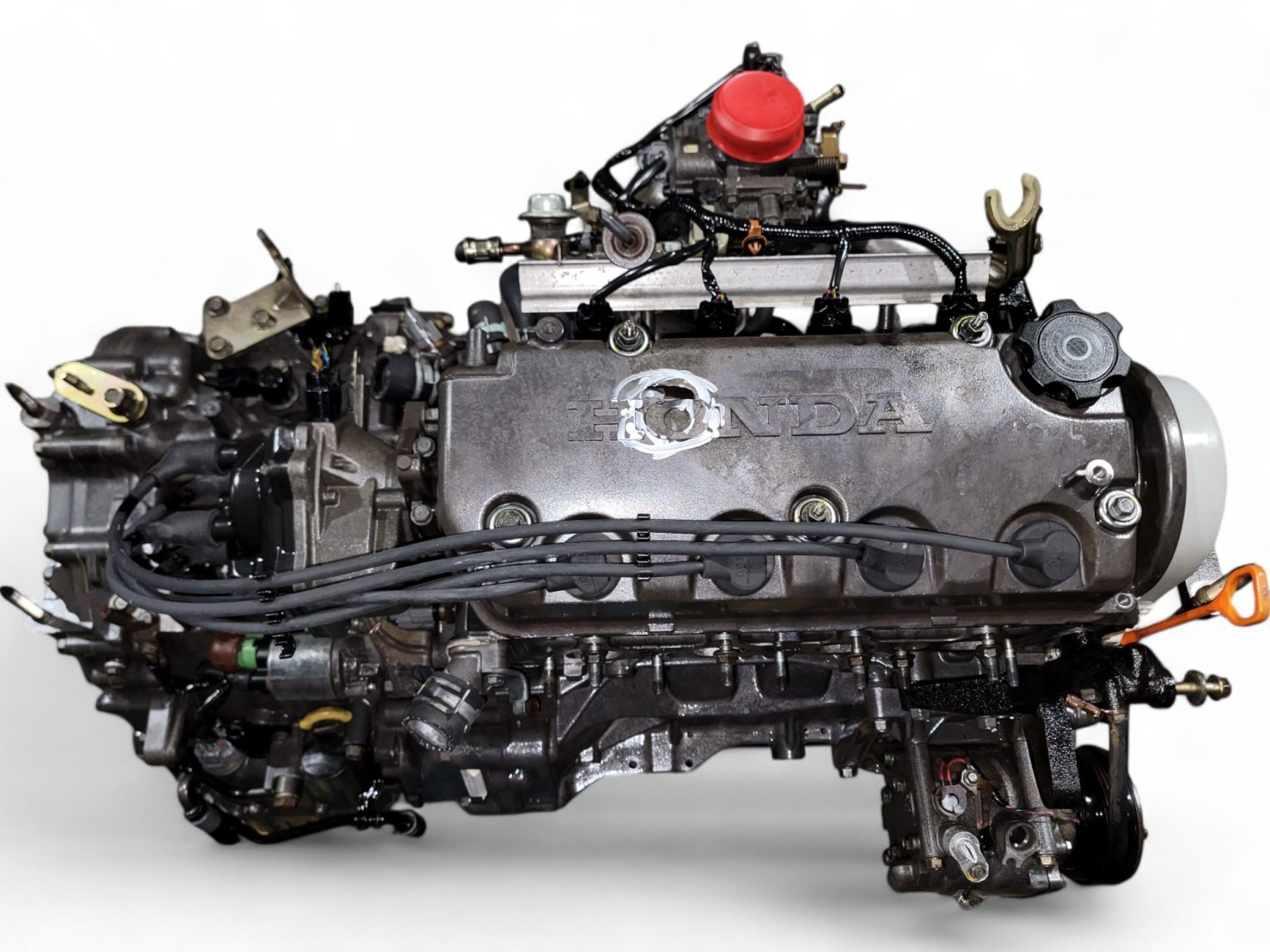

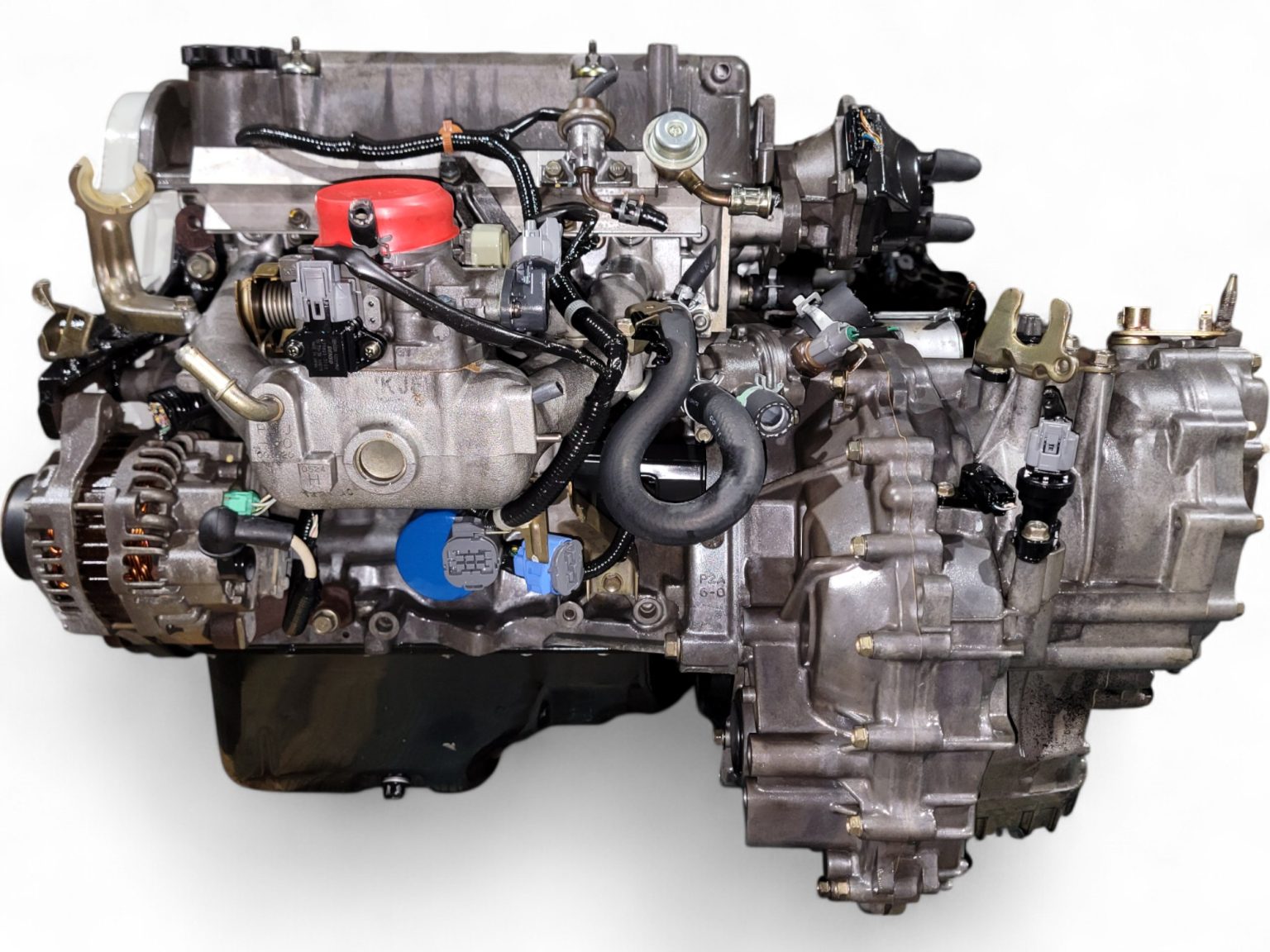

1993-1995 Honda Del Sol 1992-1995 Civic 1.5L 4CYL Engine JDM D15B 9101426 by Honda is listed under Honda Civic Engines. This comprehensive description helps you verify fitment, identify part numbers, and plan installation.

Identification and basics:

– Reference price (USD): 1499.00

Key features:

– Engine assembly focus: correct mounting geometry and verified connectors for the listed applications where specified by supplier data.

– Listing clarity: supplied as shown or stated; ancillary components only included when explicitly specified.

– Traceability: match part numbers and orientation before purchase to reduce returns.

Technical specifications:

– Refer to listing images and supplier data.

Compatibility checklist:

– Confirm drivetrain orientation and bell pattern.

– Cross-check ECU, immobilizer, and sensor compatibility for your chassis and market.

– Match emissions family and generation where relevant.

– Compare connector shapes, mounting bosses, and hose routing.

Installation guidance:

– Professional installation recommended.

– Replace wear items during install: belts, seals, filters, plugs, fluids where prudent.

– Follow torque sequences and prime the oiling system prior to first start.

– Bleed cooling system and verify fuel integrity.

Post-install checks:

– Perform compression or leak-down tests.

– Scan for DTCs and resolve wiring or vacuum inconsistencies.

– Verify idle quality, fuel trims, coolant temps, and oil pressure at operating temperature.

Packaging and handling: Inspect upon delivery and note any damage with the carrier before signing. Keep packaging until functionality is confirmed.

Buyer guidance: Only the components explicitly shown or stated are included. If your application differs from the parameters shown, select a variant that matches your configuration.

Fitment notes:

– Measure sensor leads and compare connector indexing.

– Confirm crank and cam trigger patterns match your ECU strategy.

– Verify accessory bracket offsets and pulley alignment to avoid belt walk.

Technical references:

– Use OEM literature for torque specs and lubricant grades.

– Record baseline idle, MAP/MAF values, and coolant temps for future diagnostics.

– If swapping, document pinouts and wire colors during harness integration.

Maintenance plan:

– After 100–300 km, re-torque critical fasteners where specified.

– Change oil and filter after break-in. Inspect for metal debris.

– Monitor misfire counters and long-term fuel trims.

Quality checklist:

– Inspect for oil or coolant seepage at gaskets and core plugs.

– Verify PCV routing and vacuum integrity for stable idle.

– Confirm charging output and ground paths under load.

Fitment notes:

– Measure sensor leads and compare connector indexing.

– Confirm crank and cam trigger patterns match your ECU strategy.

– Verify accessory bracket offsets and pulley alignment to avoid belt walk.

Technical references:

– Use OEM literature for torque specs and lubricant grades.

– Record baseline idle, MAP/MAF values, and coolant temps for future diagnostics.

– If swapping, document pinouts and wire colors during harness integration.

Maintenance plan:

– After 100–300 km, re-torque critical fasteners where specified.

– Change oil and filter after break-in. Inspect for metal debris.

– Monitor misfire counters and long-term fuel trims.

Quality checklist:

– Inspect for oil or coolant seepage at gaskets and core plugs.

– Verify PCV routing and vacuum integrity for stable idle.

– Confirm charging output and ground paths under load.

Fitment notes:

– Measure sensor leads and compare connector indexing.

– Confirm crank and cam trigger patterns match your ECU strategy.

– Verify accessory bracket offsets and pulley alignment to avoid belt walk.

Technical references:

– Use OEM literature for torque specs and lubricant grades.

– Record baseline idle, MAP/MAF values, and coolant temps for future diagnostics.

– If swapping, document pinouts and wire colors during harness integration.

Maintenance plan:

– After 100–300 km, re-torque critical fasteners where specified.

– Change oil and filter after break-in. Inspect for metal debris.

– Monitor misfire counters and long-term fuel trims.

Quality checklist:

– Inspect for oil or coolant seepage at gaskets and core plugs.

– Verify PCV routing and vacuum integrity for stable idle.

– Confirm charging output and ground paths under load.

Fitment notes:

– Measure sensor leads and compare connector indexing.

– Confirm crank and cam trigger patterns match your ECU strategy.

– Verify accessory bracket offsets and pulley alignment to avoid belt walk.

Technical references:

– Use OEM literature for torque specs and lubricant grades.

– Record baseline idle, MAP/MAF values, and coolant temps for future diagnostics.

– If swapping, document pinouts and wire colors during harness integration.

Maintenance plan:

– After 100–300 km, re-torque critical fasteners where specified.

– Change oil and filter after break-in. Inspect for metal debris.

– Monitor misfire counters and long-term fuel trims.